Feeding beef cattle for meat quality

The main goal for feedlot farmers is to finish cattle on high energy diets with optimal feed conversion rates (FCR) to increase carcass size. The goal is also to produce high quality meat with good marbling, a minimum of excess fat, good tenderness and flavour.

The role of processing plants is to slaughter feedlot cattle and process carcasses into wholesale and retail cuts. Processing cannot change meat quality, but can add value by breaking the carcass down into packaged products of differing portion size and value, according to beef type and marbling content. Processors can also age meat to increase its flavour and retail value.

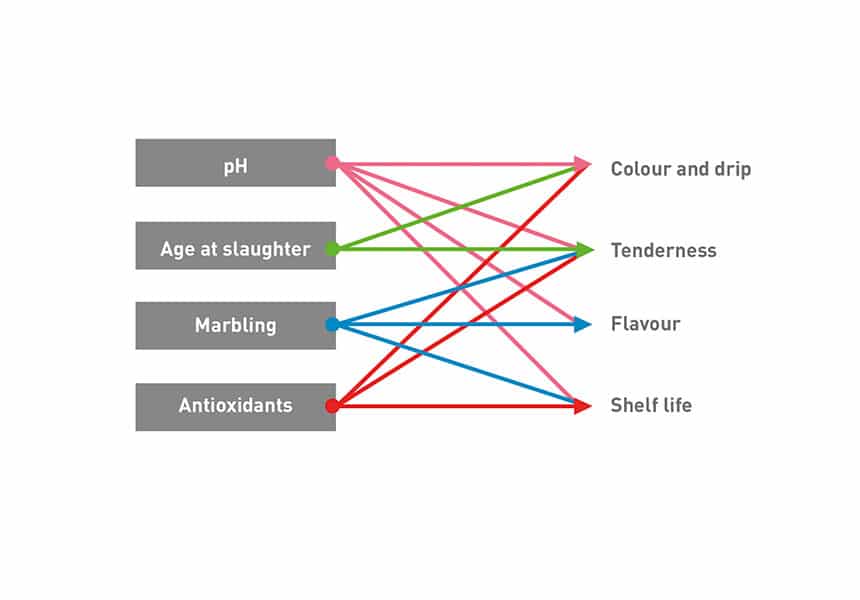

Meat quality

Meat quality is assessed by colour, tenderness, and flavour, but mostly by its marbling. Marbling describes the fat content inside the beef muscle, known as intramuscular fat. This is located between and within muscle fibres and its greatest deposit is achieved during the later stages of the growth process (Steven M. Lonergan et al., The Science of Animal Growth and Meat Technology, Second Edition, 2019). While external fat around the meat and the internal organs is not desired by consumers, intramuscular fat drives meat quality and purchasing decisions.

Strategies to impact meat pH and reduce dark cuts

Feed high-energy diet during finishing:

• ensures adequate muscle glycogen

Avoid feed withdrawal:

• creates lack of energy for glycogen replacement

• feed into the trough, keeping cattle calm and limiting competition

Avoid acidosis which:

• increases agitated behaviour

• reduces feed intake

Specific supplementation, especially in the case of prolonged transport/lairage:

• glycerol, propylene glycol, dextrose, electrolytes, etc.

Supplementing Selsaf® to improve meat quality

Selsaf® is a unique source of highly bioavailable organic selenium. It contains two different types of organic Se, selenocystein (Se-Cys) and selenomethionin (Se-Met). Selsaf® helps the body combat oxidative stress, countering the detrimental stress effects on animal performance, both in the short term, due to Se-Cys, and in the long-term due, to Se-Met.

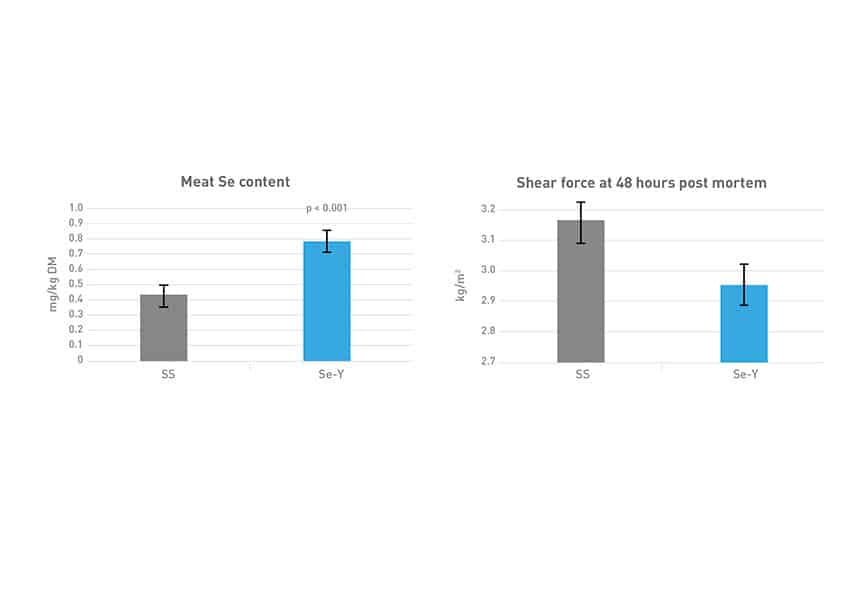

Charolais heifers were supplemented 60 days before slaughter with 0.2 mg Se/kg DM of Se from Sodium Selenite (SS) or Selenized Yeast (Se-Y; Selsaf®).

Selsaf® increased Se bioavailability in the muscles, leading to lower oxidation of intramuscular fat and protein, contributing to better meat tenderness. Selsaf® also improved organoleptic parameters in the meat, directly related to its appearance and the customer’s purchasing decision.

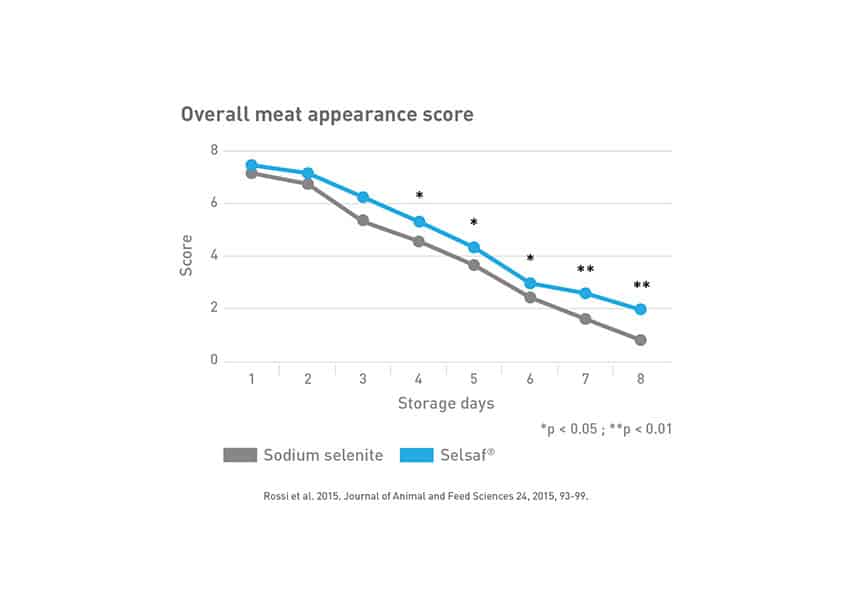

Selsaf® supplementation to increase product shelf life

Selsaf® supplementation improves overall meat appearance (color, odor and surface wetness) from the 4th day in storage. The trial also confirmed the effect of Selsaf® on meat tenderness by measuring the shear force of cooked beef after 2 days in storage.